RAY Egelhof - Gas burners "EG" - series

RAY Egelhof - Gasburner “EG” - series are industrial duobloc burners. They are built according to a modular principle and consist of the burner, a windbox, a separately installed combustion air fan, fuel supply line(s) and control system. RAY Egelhof - Gasburner “EG” - series cover a capacity range from 232 (792 MBTU) kW - 69.767 kW (238,048 MBTU).

RAY Egelhof - Gasburner “EG” - series are very versatile and can use all technical combustible gases, biogases, hydrogen, LPG and process gases. Separate or parallel combustion of gaseous fuels is possible.

The digital combustion management system that is used as standard (other options are available on request), simplifies the operation, monitoring and maintenance of the burner.

Due to the modular burner design and the flexibility it provides, it can be used for a wide variety of special applications. Individual project planning, a short planning phase and high system availability are guaranteed.

For further information, please contact us - our team will be happy to support you!

Key dara: RAY Egelhof - Gasburner "EG"-series

| Applications | LTHW-boilers, HTHW-boilers, Thermal fluid heaters, Steam-boilers, Heat generators |

| Fuels | all technical combustible gases, biogases, hydrogen, LPG and process gases, separately or simultaneously |

| Sizes | 17 Sizes |

| Operating range | 232 - 69.767 kW |

| Air preheating | max. 250°C |

| Turndown | max. 1:12 |

Key dimensions at a glance (for download)

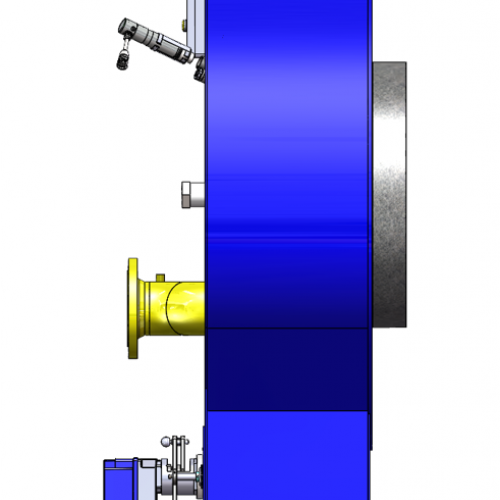

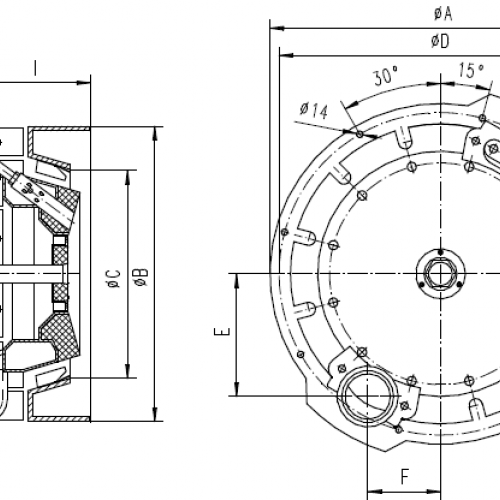

Burner types EG 150 - 700 Cross section

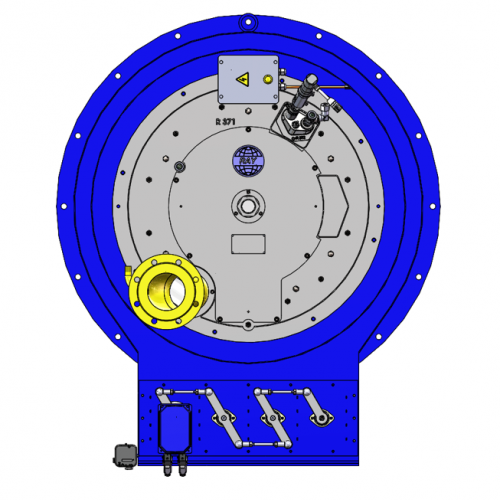

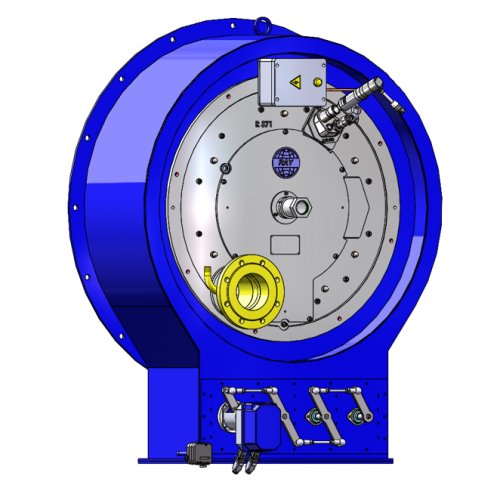

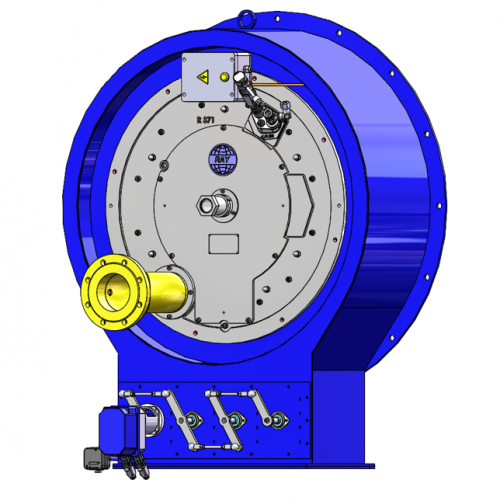

Burner types EG 150 - 700 Front view

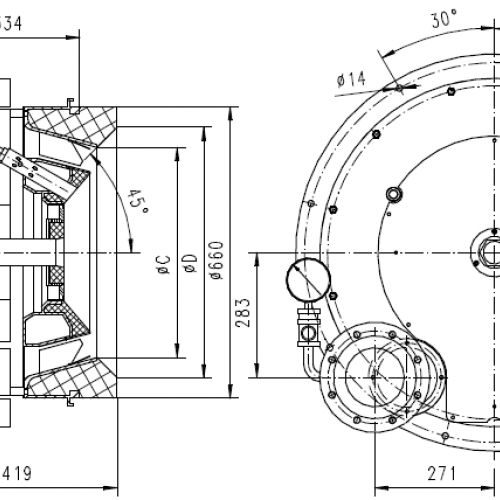

Burner types EG 800 - 1500 Cross section

Burner types EG 800 - 1500 Front view

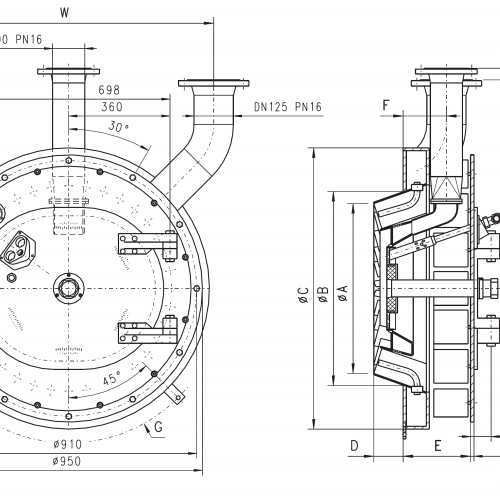

Burner types EG 2000 - 3500 Cross section

Burner types EG 2000 - 3500 Front view

Burner rating /-weight and -dimensions

| Model | Rating min. | Rating max. | Windbox with air damper unit Type |

Windbox with air damper unit Type |

Weight burner with windbox | ØA | ØB | ØC | H | I |

|

kW MBTU |

kW MBTU |

DLV | SLV | kg | mm | mm | mm | mm | mm | |

| EG 150 |

232 792 |

1.744 5,951 |

35 | 15 | ca. 159 | 638 | 540 | 370 | 91 | 195 |

| EG 250 |

349 1,191 |

2.907 9,919 |

35 | 25 | ca. 159 | 638 | 540 | 370 | 91 | 195 |

| EG 350 |

407 1,389 |

4.070 13,887 |

35 | 35 | ca. 159 | 638 | 540 | 370 | 91 | 195 |

| EG 500 |

581 1,982 |

5.814 19,837 |

70 | 50 | ca. 250 | 750 | 660 | 445 | 105 | 254 |

| EG 600 |

698 2,382 |

6.977 23,806 |

70 | 60 | ca. 250 | 750 | 660 | 460 | 105 | 254 |

| EG 700 |

698 2,382 |

8.140 27,774 |

70 | 70 | ca. 250 | 750 | 660 | 460 | 105 | 254 |

| EG 800 |

756 2,579 |

9.302 31,738 |

100 | 80 | ca. 387 | 900 | 660 | 476 | 274,5 | 419 |

| EG 1000 |

965 3,293 |

11.628 39,675 |

100 | 100 | ca. 387 | 900 | 660 | 498 | 274,5 | 419 |

| EG 1250 |

1.221 4,166 |

14.535 49,593 |

125 | 125 | ca. 440 | 900 | 660 | 498 | 274,5 | 419 |

| EG 1500 |

1.628 5,555 |

18.604 63,477 |

150 | -/- | ca. 480 | 900 | 660 | 538 | 274,5 | 419 |

| EG 2000 |

1.977 6,746 |

23.256 79,349 |

200 | -/- | ca. 630 | |||||

| EG 2500 |

2.326 7,936 |

29.070 99,187 |

250 | -/- | ca. 670 | |||||

| EG 3000 |

2.907 9,919 |

34.884 119,024 |

300 | -/- | ca. 680 | |||||

| EG 3500 |

3.400 11,601 |

40.698 138,862 |

350 | -/- | ca. 685 | |||||

| EG 4000 |

3.880 13,239 |

46.512 158,699 |

400 | -/- | ca. 700 | |||||

| EG 4500 |

4.360 14,876 |

52.326 178,536 |

450 | -/- | ca. 720 | |||||

| EG 6000 |

5.820 19,858 |

69.767 238,045 |

600 | -/- | ca. 800 |

General product features

- Reliable compliance with limit values under practical conditions

- Robust construction

- Durability

- Reliability

- Low maintenance costs

- Slide- in air guide unit

- Highly efficient combustion technology

- Stable flame